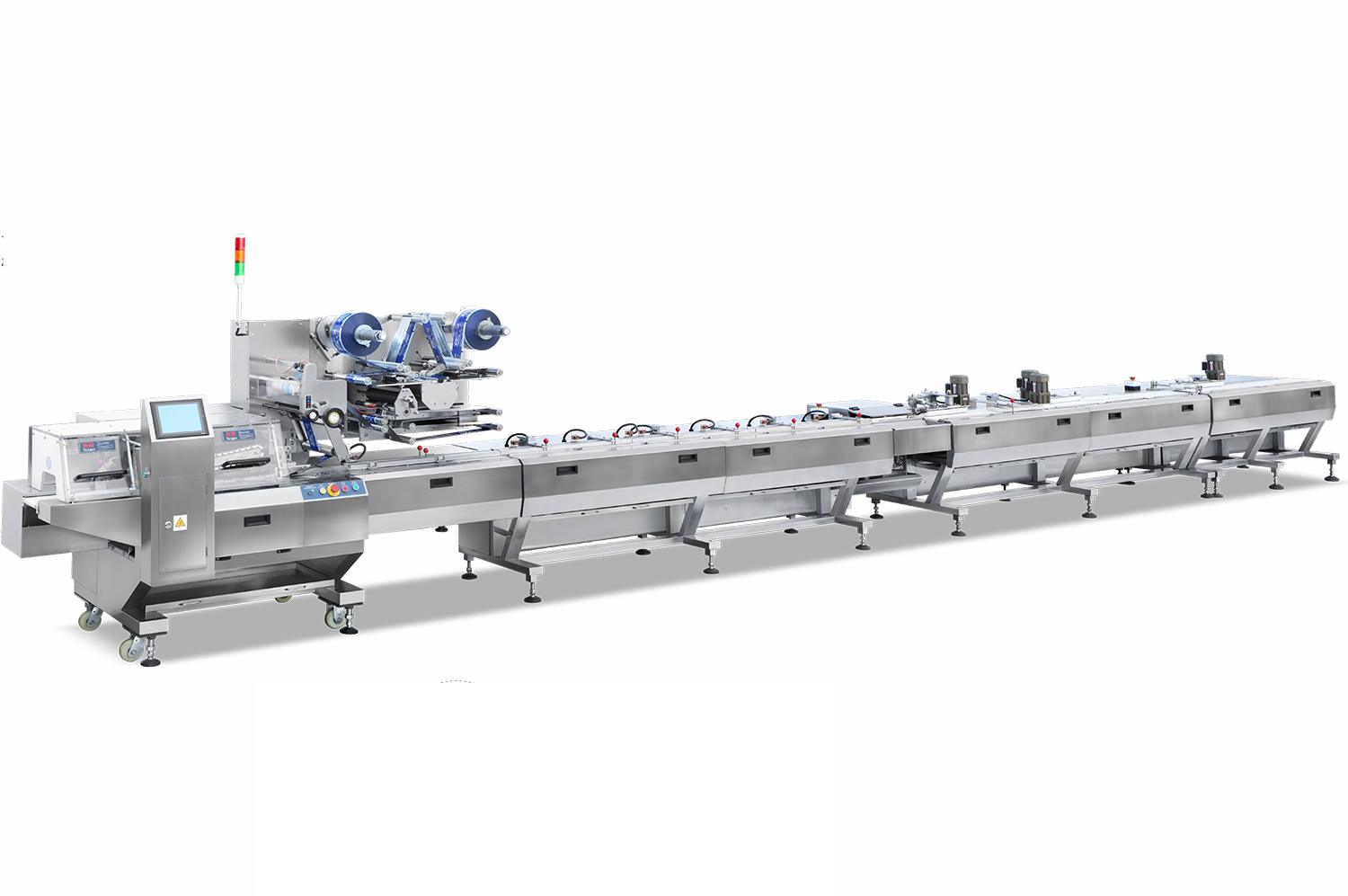

DXD-660高速自动理料枕式包装线

USE用途

包装机型号:DXD-660高速自动理料枕式包装线

This machine is suitable for packing chocolate, wafer, confectionery,coated product and so on.

适用于巧克力、威化、膨化、米果、面包、蛋糕、瑞士卷、糖果等及其涂层制品的包装。

自动理料枕式包装线的主线物料分配系统采用中央集成控制系统,根据产品来料速度和数量自动调整分配;理料单元通过伺服和PLC控制将产品有序,顺畅,无损伤的进入包装系统,实现产品输送,整理排队,供料自动化,定位准确,无空包多包现象;根据生产能力,可选多级理料单元,包装单元数量(包装机可根据产品选配)。

The main line material distribution system of automatic material handling pillow type packaging line adopts central integrated control system, which can automatically adjust the distribution according to the product incoming speed and quantity; the material handling unit will enter the packaging system orderly, smoothly and undamaged through servo and PLC control, so as to realize the product transportation, sorting and queuing, automatic feeding, accurate positioning, and no empty and multi package phenomenon; according to the production capacity, the system has the advantages of easy operation, convenient operation and high quality , multi level material handling unit and number of packaging units (packaging machine can be selected according to the product).

MAIN TECHNICAL PARAMETERS包装机的主要技术参数

DXD-660

Max.Production Capacity | z大生产能力 | 1200包/分(bags/min) | |||||||

Packing Range / Width Height | 包装范围(袋长由 切刀数决定)/ 袋长 宽度 高度 | 55-200mm 15-60mm 5-30mm | |||||||

Max.Dia.of Film | 包装膜z大直径 包装膜z大宽度 | 390mm 300mm | |||||||

Gross Power Power Supply | 总功率 电源 | 9.6kw 380V 50Hz | |||||||

Gross Weight Overall Dimension | 总重量 包装机外形尺寸 | 1600kg 9800×1000×1700mm | |||||||

Packing Material | 包装材料 | OPP、CPP、PET镀铝膜、铝塑膜、纸塑、纸胶等单层多层等可热封材料 建议使用外层PET厚度0.013mm,内层CPP厚度0.023~0.027mm ,复合低温膜 OPP、CPP、PET Metallized film,Al-plastic film,Paper-rubber complex Suggest to used wrapping film with material of PET13/CPP23-27 | |||||||

Note: We can design and manufacture according to customer's special needs. 注:用户如有特殊规格,本公司可另行设计制造.

Characteristics 包装机特点

1 This machine is driven by servo motors, which helps achieve more

convenient operation and easier maintainance

2 This machine adopts wrapping film auto splice device, which helps

the machine achieves splicing of film without stopping machine

3 It adopts 304 stainless steel cover

4 Famous brand of control system, makes sure of stable working of

machine

5 Touch screen and plc help operating of machine more intuitive.

6 Adopts water chiller for chocolate products, to prevent chocolates

from being melt during packing.

7 To ensure fast packing speed, our machine uses 3sets of middle

seal wheels together with preheating.

8 The machine is equipped with remote control system, which makes

solving of program problems much easier.

1)伺服控制,使得操作更加方便,维护更加简单;

2)自动接膜装置,实现了接膜不停机;

3)整机外壳采用304不锈钢;

4) 品牌的控制系统,保障了整机操作的稳定性;

5)触摸屏,PLC使得操作更加直观;

6) 对于巧克力产品采用水冷结构,保护巧克力产品在包装过程中

和设备的接触面不易融化;

7)三道纵封加预热块的设计,保障了设备的高速运行;

8)包装机配备远程控制系统,能更加方便的解决软件问题。

理料线相关资讯

- 枕式包装机的材质选择与性能分析

- 枕式包装机的材质选择与性能分析:如何满足多样化需求

- 枕式包装机:制造工艺与技术创新并进

- 枕式包装机:制造工艺与技术创新

- 枕式包装机:长期稳定运行,保障生产效率与产品质量

- 枕式包装机:应对复杂包装需求的智能设备,提升生产灵活性

- 枕式包装机:未来包装技术的发展趋势与前景展望

- 枕式包装机:为产品包装带来革命性变革,开创包装新纪元

- 枕式包装机:提升工厂整体包装水平,增强市场竞争力

- 枕式包装机:提升工厂包装竞争力的关键要素与策略

- 枕式包装机:适应各种包装环境,打造完美包装效果

- 枕式包装机:实现自动化包装的智能选择,引领行业潮流

- 枕式包装机:实现自动化包装的智能设备

- 枕式包装机:确保产品包装的紧密度与美观度

- 枕式包装机:确保产品包装的紧密度、美观度与一致性

- 枕式包装机:品质与创新并重的包装选择,引领行业风尚

- 枕式包装机:满足大规模生产需求的优选设备

- 枕式包装机:满足大规模生产的包装设备

- 枕式包装机:流水线作业的高效选择

- 枕式包装机:流水线作业的高效包装设备

- 枕式包装机:科技驱动的包装优化设备,助力企业转型升级

- 枕式包装机:精准包装,提升产品价值与品牌形象

- 枕式包装机:打造高端包装效果的必备设备

- 枕式包装机:包装行业的创新之选,推动产业升级