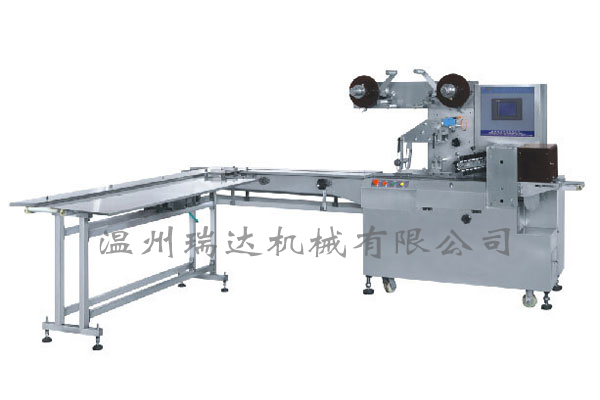

Pillow packing machine fault causes and solutions

Pillow packing machine is applicable to a wide range,Although the appearance is simple, but the process of operation should also be in accordance with the formal way and method, if pillow packaging machine failure, then the fault causes and solutions are what?

1. When the pillow packing machine product seal appeared the situation of wrinkling, this is because the pillow packing machine operating temperature is too high, and the speed is too slow to cause; The solution is to adjust the temperature to the appropriate range, which is to increase the speed of the pillow packaging machine.

2. When the cutting knife of pillow packaging machine is cut on the product, it indicates that the height of the knife holder of pillow packaging machine is not the appropriate height, and the packaging speed is too fast, the push rod and the cutting knife are not carried out at the same time, the solution at this time is to adjust the packaging speed of pillow packaging machine and adjust the height of the knife holder.

3. When the cutting position of the pillow packaging machine deviates from the color mark, it is proved that the color mark of the film is too light and the film drives to slip. At this point, the solution is to adjust its sensitivity; Switch the tracking mode of pillow packing machine to “ Tracking cutting & throughout; .

4. When the temperature meter of pillow-type packaging machine cannot control the temperature, this is the damage of the solid-state breaker, and may be the temperature control meter is broken, the solution is to replace the temperature control meter, replace the solid-state breaker.

5. When the pillow packaging machine seal does not seal the situation, this may be the pillow packaging machine speed is too fast, needless to say this time the solution is to reduce the pillow packaging machine speed.