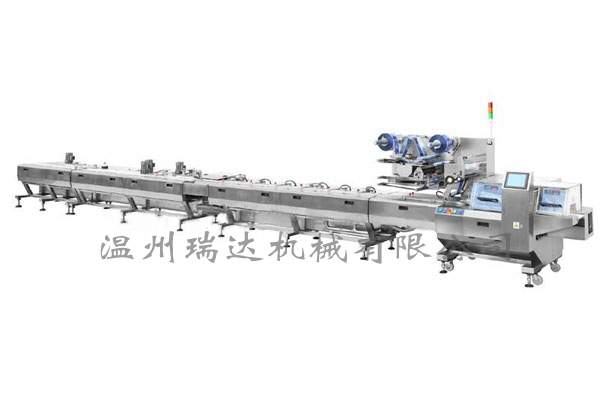

Pillow packing machine specifications and models

Pillow packing machine specifications and models?

Pillow type packing machine product demand is increasing day by day, so the manufacturer that produces a product also increases a lot, and the specification of the product and model also can undertake custom. But in the purchase of products in the purchase of time not because the price is cheap or expensive to choose, but should be more than a survey, so as to choose the right products.

Pillow packing machine several relatively simple maintenance methods:

First, the temperature is too high, the speed is too slow, envelop outer heat resistance is poor, the seal will appear wrinkle marks maintenance method is to adjust the speed, reduce the temperature, change the film material.

Second, the air pressure is not right, the cylinder swing rod is loose, the heating temperature is low, the hot press roll and the transmission roll are not parallel to appear when the heat seal is bad, the maintenance method is to adjust the parallelism, adjust the temperature and air pressure to tighten.

Three, the speed is too fast, envelop inner layer thermal sealing is poor, when the temperature is too low, sealing leakage or not firm, the maintenance method is to slow down the speed, raise the temperature, replace the film material.

And it should be noted that the induction aviation plug must be inserted before the power supply, and lock the screw; Do not use metal cover and container, and do not press the start button on the metal surface, otherwise the machine will be damaged; During the working process, touch the surface of the induction head frequently to check whether it is overheated. If hot hands are found, stop heating and work after cooling; There will be high pressure in pillow-type packaging body, the bottom plate has electricity, maintenance must pay attention to, so as to avoid personal danger.

Four, the knife base is too high or too low, the packaging speed is too fast, push rod and cutting knife is not synchronized, the cutter will cut on the product maintenance method is to reduce the packaging speed, adjust the height of the end sealing parts, make the center of the sealing knife in the middle of the height of the product.

Five, the color of the film color label is too light, and the film drives to slip. When the tracking of the color label is not opened, the cutting position will deviate from the color label. In the man-machine dialog interface, switch the tracking mode to tracking.

Tips: pillow packaging machine products have been different from the past, the society in progress, science and technology in the development, people's living standards are also improving, as people's demand for products increase, promote the product is also constantly with The Times. The company's products after many years of research and development and innovation, products can not only meet the needs of enterprises, and in the after-sales aspects are guaranteed.